Gypsum Lab Services

Gypsum CalcinationCalcination is the practice of dehydrating gypsum into plaster or stucco through a batch or continuous process which includes heating the gypsum to evaporate the crystalline water. Typically, free water is removed in an initial process at approximately 45℃ and crystalline bound water is removed in a second process at 120-180℃. Many systems additionally include options for grinding capacity before, during and after calcination, depending on the intended products. Commercial equipment to perform the calcination process include rotary calciners, flash calciners, kettle calciners and fluidized bed calciners to make beta plaster or autoclave calciners to make alpha plaster. The various calciner systems have different capacities, residence times and efficiencies and produce different plaster properties which dictate their most appropriate use. Do you need help determining which equipment is the best option for your gypsum application? Innogyps has extensive experience in performing calcinations on natural rock gypsum, FGD and phosphogypsum and can help you to evaluate your supply of gypsum. We have the lab scale capability to dry, crush and grind if your gypsum material is not yet processed. We can operate our lab scale kettle calciner a) batchwise to produce high water demand wall plasters, b) batchwise to produce low water demand aridized plaster for moulding or casting applications or c) continuously to produce low water demand stucco for applications such as a gypsum board line. Our lab kettle is an 80 L electrically heated calciner that produces stucco at a rate of 10 kg/ hour. The calcination is controlled by a thermocouple within the stucco bed that changes the feed to maintain a constant temperature, just like a full sized industrial calciner. Calcination temperature can be set at approximately 135-180℃ and can be tuned to minimize residual gypsum and soluble anhydrite production and maximize hemihydrate production. The kettle stirring rate can be adjusted by a variable DC motor controller and all calcination exhaust is drawn through a cyclone and baghouse dust collection system. Contact us to learn more about calcining gypsum. |

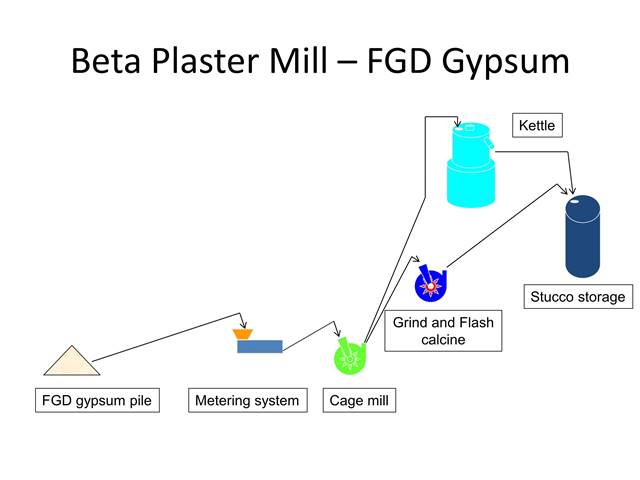

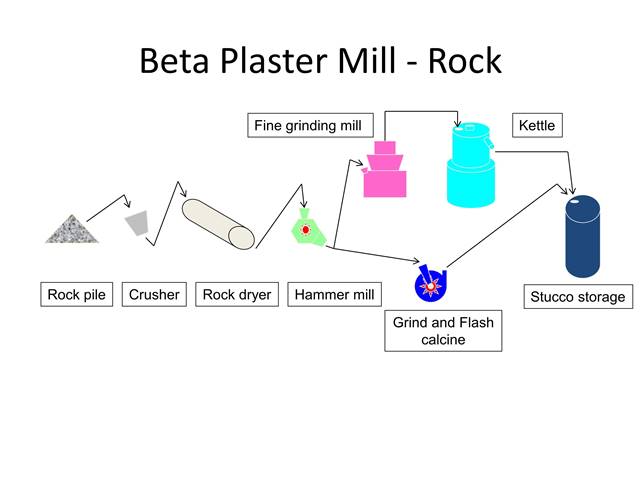

FGD Calcination  Rock Calcination |